As one who has been performing vehicle troubleshooting since the early '80s, a lot has changed since then. I still remember the first time I saw a scan tool connected to a vehicle display sensor information; I was amazed and had a strong feeling that big things were on the horizon. Fast forward to today, and now we have multiple networks talking to a multitude of controllers all necessary for proper vehicle operation, and it is our job to fix them when problems arise. However, professional service technicians like yourself still need basic tools to address challenges on vehicles regardless of the level of technology the vehicle possesses. That's what we’ll be covering in this article.

1. Scan tools and code readers

Even the most basic scan tools and code readers are indispensable for diagnosing modern vehicles. They interface with a vehicle's onboard diagnostics (OBD) system to retrieve diagnostic trouble codes (DTCs), providing a starting point for troubleshooting. However, the service technician needs to be fully aware of each tool's limitations and how the tool should be validated for accuracy. For example, generic OBD-II diagnostics have been standardized. However, each manufacturer can take these standards further and implement specific diagnostic codes and information. If that information is available, it is up to the tool manufacturer to make sure that data is being properly interpreted. Manufacturer-specific trouble codes have specific meanings, and if the tool's internal reference libraries are inaccurate, the technician could very easily end up on the wrong pathway. Today, there is a plethora of diagnostic scan tools available to service technicians with varying features and functions. Let’s explore these to learn more.

Key features

Code reading: As mentioned earlier, quick access to DTCs and their meanings is powerful, one just needs to be aware of potential challenges.

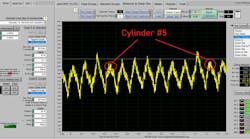

Live data: Accessing live data is extremely powerful, some tools allow the service technician to recall and view custom groups of data which can lead to greater productivity. Additionally, some tools will allow the technician to visualize data through charts and graphs which is something that I love to see in tools. Another nice feature some tools offer is the ability to perform output tests or specific system tests while logging and monitoring data which can be extremely powerful.

Advanced functions: Some tools offer ECU flashing, programming and coding, security functions, and ADAS service operations such as sensor recalibration as an extension to calibration fixtures and aiming equipment (Figure 1).

2. Multimeters and oscilloscopes

Electrical issues require precise measurements which can provide the technician with valuable insight. Digital multimeters (DMMs) (Figure 2) and oscilloscopes provide one with instantaneous information and/or the ability to record values over time. Whatever challenge the service technician may be facing, they will need to possess the foundational knowledge needed to ensure the data produced during testing is providing actionable information. For example, a technician may be facing a situation where a scan tool is unable to pull any information from the vehicle’s data bus. In this situation, the technician will need to have access to service information and be able to understand how to physically test for proper power, ground, and network wiring. Once the data bus has been restored as operational, the scan tool can then be used to further analyze the vehicle systems.

Key features

Voltage and resistance measurement: Essential for checking battery health, sensor outputs, proper power and ground module support, and wiring integrity.

Waveform analysis: Oscilloscopes display signal waveforms crucial for diagnosing sensors and communication networks.

Case study

Over on Diagnostic Network (diag.net) there was a recent post by a member seeking help on a communications problem on a 2015 Ford F-250 Super Duty Lariat 6.2L. The vehicle exhibited a no crank condition with a DTC U0100 — lost communication with ECM/PCM "A". The technician was analyzing the CAN communications line with a PicoScope using their serial decoding tool and although it appeared that there was communication signaling on the physical bus lines, the PicoScope was unable to interpret until the PCM was removed from the network (Figure 3).

The cause here was that one of the power supply circuits to the PCM had a large voltage drop which was insufficient for proper module operation. The module was trying to become operational however this led to it excessively loading the communication circuit. To read the entire discussion, visit diag.net/msg/m1rbdedulr6s201vsi9378tcw6.

3. Battery and charging system testers

The low-voltage battery should always be respected as ground zero. Proper maintenance of a vehicle's battery and charging system is critical, especially in hybrid and electric vehicles. These testers assess the health and functionality of batteries, alternators, and related components. Testing the battery upfront can not only save you valuable diagnostic time but may present a preventative maintenance upsell.

Key features

Battery health check: This evaluates the condition of batteries and is something we do on every vehicle maintenance service. The results are posted to the work order along with any notes, pictures, and in-service dates as needed. When testing a battery, it is important to understand what kind of test is being used to assess its condition. In some cases, one may need to place a fully charged battery under 1/2 of the cold cranking amps rating while monitoring battery voltage. The first one of these I ever used was the Sun VAT 28. Today in my shop we have a Snap-on load tester along with the Associated Equipment 6042 (Figure 4).

Charging system analysis: Same applies here, one needs to be aware of how the system is being tested. The small hand-held testers for the most part do a good job at assessing charging systems however, carbon-pile testers can place the system under load to activate the charging system to operate near max capacity. This is especially true for hybrid and battery-electric vehicles. The performance of the DC-DC chargers on these can be quickly checked. Please refer to service information on the specifications and proper testing methods before proceeding.

4. Diagnostic software and databases

Access to up-to-date diagnostic software and technical service information databases is essential for successful vehicle diagnostics. Wiring diagrams, component locators, connector layouts, and service operations all play a critical role in achieving success.

Key features

Vehicle-specific information: Technical service bulletins (TSBs), recalls, and service and repair operations provide a pathway to success. Oftentimes a technician will find themselves performing research before even entering the vehicle. Surfacing a TSB or a recall may provide valuable insight and/or a new perspective one would not otherwise achieve.

Software updates: With the plethora of modules deployed on today’s vehicles one should always consider the possibility that a vehicle problem may be solved by a software update (Figure 5). Updating software in modules is something we perform often in my shop but before updating one should always justify the procedure. If the manufacturer advises that the update should only be administered if problem 'X' exists, then this is what should be performed. Sometimes getting the latest version of software in the vehicle may solve other issues that have yet to surface. It has been my experience that many software update packages come with very little to nearly zero release notes. In the computer industry, it is standard practice to issue release notes about what the software is offering. What this means is that although it’s not documented there may be something in that package to address whatever it is you’re faced with. In this case, I opt to add the latest available version.

5. Tire pressure monitoring system (TPMS) Tools

With TPMS (Figure 6) being a standard feature in today’s vehicles, having the right tools to service and diagnose these systems is essential for ensuring vehicle safety and compliance. We have found that we need more than one tool in our shop because some vehicles simply don’t want to cooperate with some tools.

Key features

Sensor programming: This programs new TPMS sensors to the vehicle and reindexes after rotation.

Diagnostics: Helps to identify issues with the TPMS system.

6. Fluid analysis tools

Fluid condition is a vital indicator of vehicle health. Tools for analyzing coolant, and brake fluid, can preemptively identify issues before they lead to major failures (Figure 7).

Key features

Contamination detection: Identifies particulates and contaminants in fluids.

Conclusion

Diagnostics is an essential part of the repair process and can be extremely challenging. By using the right tool at the right time, the service technician can hone in on the problem by providing clues and data points that will lead to an effective outcome. This requires automotive technicians to stay abreast of the latest tools and technologies. By equipping themselves with many of these essential diagnostic tools, professionals can ensure they are prepared to tackle the challenges posed by modern vehicles. In our shop, we often find problems manifesting from improper maintenance, and this is why we use many of the tools above during preventive maintenance services. Our motto is: “We can fix it, but we’d rather maintain it!” Using these tools to document conditions helps to promote proper vehicle care and can lead to increased revenue.